The Ripple Road Process

When making syrup it generally requires two people to do the boiling. We typically process between 45-50 gallons of syrup per hour, so the job of filtering the syrup is constant. This requires the attention of one person. The other person watches the evaporator and makes sure the syrup is of the right density(consistency) when taking it off.

Preparation

We have a little over 200,000 feet of tubing in our woods. This is close to 40 miles. These lines have to be walked almost continuously during the sugaring season and at least 4 or 5 times during the offseason to check for leaks. These are caused by squirrels chewing on the lines and also trees falling on them. It is important to have no leaks because leaks affect the vacuum levels which lead to less sap yield.

Pictured: Neil is tapping a tree and putting the spout in. Also pictured, Tonya is putting spouts on.

Collection Technology

This vacuum booster was installed in our new woods to accommodate the lines that only run at a 2% pitch back to the sugar house. Since these taps are so far away (about a half-mile) this ensures there will always be adequate vacuum to these taps.

Pictured: (Bottom/Left) The vacuum pump which "pulls" the sap out of the trees and down the hill.

Waking Up To Full Sap Tanks

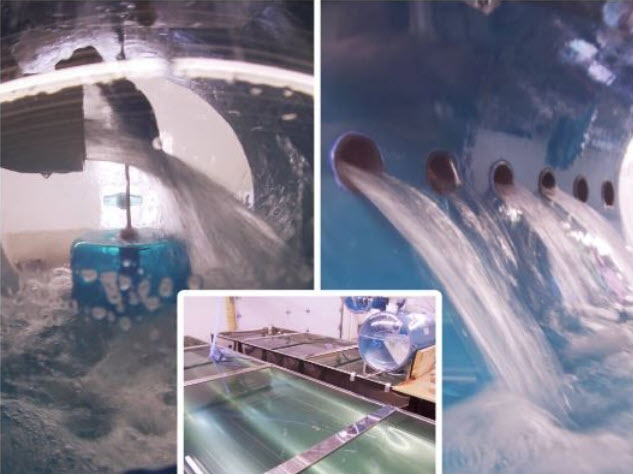

Here you can see sap coming into the releaser in the sugarhouse. In the picture on the far left, it's running at approximately 1,200 gallons per hour.

In the smaller image towards the bottom of this picture, you'll see what it looks like when we get to the sugarhouse in the morning and get to view full tanks.